Understanding Wire

First, let’s discuss wire gauge.

Wire Gauge

For the purposes of this course, every time I talk about wire gauge, I am always referring to the American Wire Gauge (AWG), which is also sometimes known as the Brown & Sharpe Guide. All of the product links throughout the course also take you to items measured in AWG.

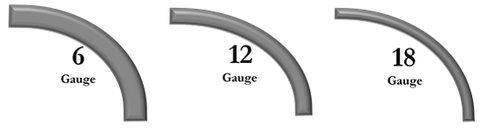

In simplest terms, gauge is the thickness of the wire. The smaller the size, the higher the number. It seems counterintuitive, but there we are. For example (these are not to scale):

You will notice that the thicker the wire, the smaller the gauge number.

Important Things to Consider When Purchasing Wire

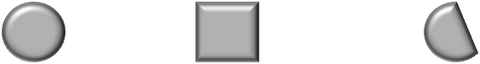

Here are some important things to consider when purchasing wire, starting with shape. For the purposes of this course, there are three main wire shapes you should be aware of: Round, Square and Half-Round.

Round wire is the most common and by far the most readily available wire. You can use round wire for almost any project.

The majority of the projects in this course use round wire, with the exception of Project Ten, the Simple Wire Wrapped Cabochon Pendant, which uses a combination of square and half round wire. You will find that it is more effective to use wire with at least one flat side when working with undrilled cabochons or using basic and intermediate techniques to set stones. More on this in the lessons on Project Ten.

I discuss wire material in detail in the lecture on metal choices, but I will just mention here again that it’s one of the most important considerations when buying the right wire for your project.

Wire temper is the basic consistency or hardness of the wire. It’s a pretty significant consideration, of which there are three main categories: Dead Soft, Half Hard and Hard.

Dead Soft wire is extremely flexible and easy to work with, but it’s easily pushed and pulled out of shape. Half Hard wire is firm and springy, but is still relatively malleable. Hard wire is much more difficult to work with, but it allows you to form more permanent shapes.

I use Dead Soft wire for certain types of stone setting and very rarely use Hard wire, if ever. I find that in general, Half Hard wire is the Goldilocks wire, you know not too soft, not too hard, but juuuust right! While Dead Soft and Hard wire definitely have their uses, all the projects in this course use Half Hard wire.

Just a couple more things before we move on.

First, all the projects in this course assume that you have straightened your wire. This is very important for the final look of your piece. Kinked and twisted wires have a way of making a finished product look sloppy. I have made suggestions and provided links for wire straightening tools.

And finally, it’s important to know that when cutting wire, the ends sometimes fly across the room at unexpected times and in unexpected directions. You could totally shoot your eye out, kid!

One way to help prevent this is by holding the end piece between your thumb and forefinger while cutting the wire. Of course, you could always just wear goggles! Just saying!

Leave a comment